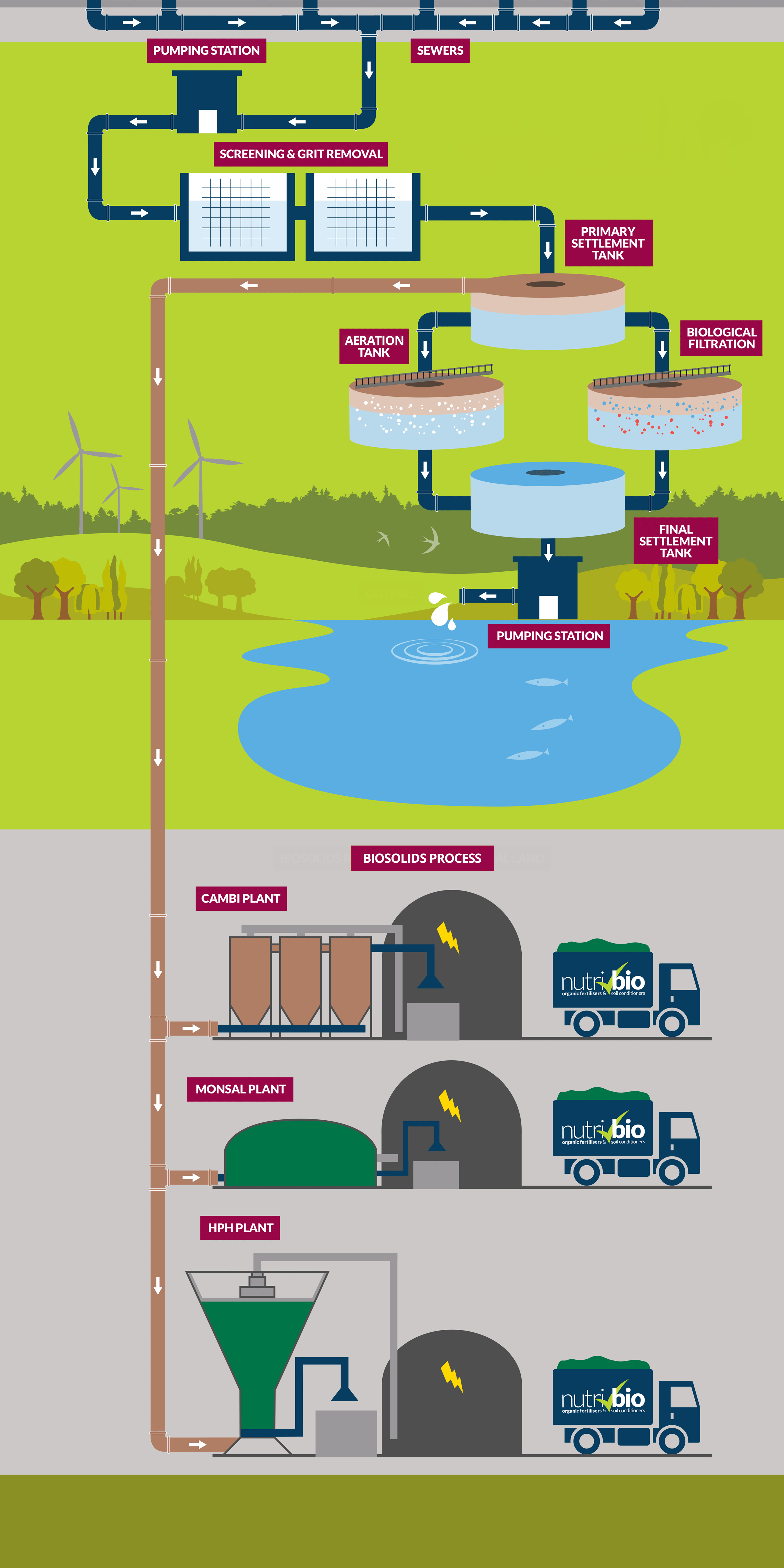

PUMPING STATION

Wastewater is pumped underground to lifting stations where it is chemically treated and sent either through the sewerage system, or by road, to treatment centres for processing and separation.

Wastewater is pumped underground to lifting stations where it is chemically treated and sent either through the sewerage system, or by road, to treatment centres for processing and separation.

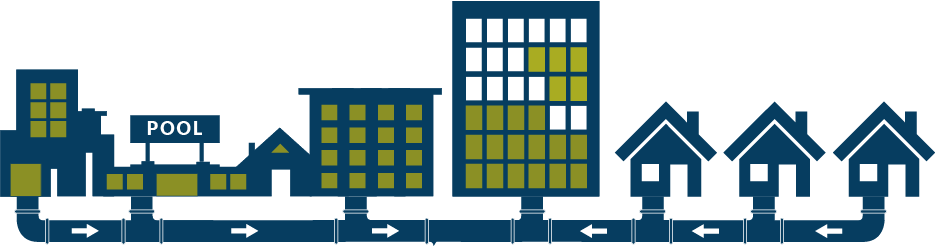

Transport raw sewage in urban areas to minor treatment centres for primary treatment, or to wastewater recycling centres for processing.

Lots of unwanted things get into sewers: cans, plastic bags, nappies, even wallets and false teeth!

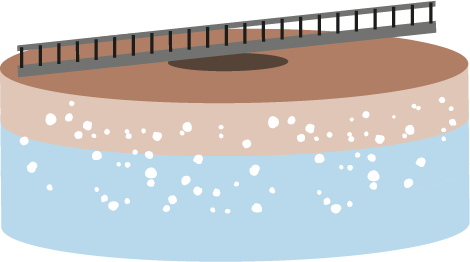

Next the solids are removed by pumping the wastewater into large, deep sedimentation tanks. Heavy solids are allowed to settle out and then taken away for further treatment, to become biosolids.

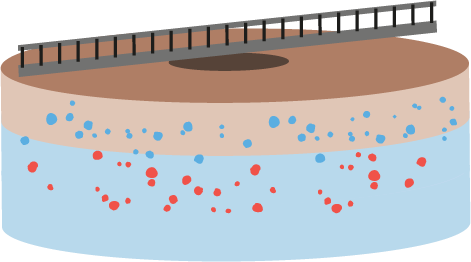

Chemicals and air are pumped through the sludge, to activate the bacteria within it, which degrade the remaining pathogens.

The wastewater passes over a biological filter, where it is exposed to billions of bacteria, which attack the remaining solids and pathogens, breaking them down and straining the sludge.

Gravity feeds the water through secondary clarifiers, where bacteria continue to break down pathogens, until the water is drinkable.

From the final settlement tank the water is pumped to an outfall, at a selected site in the local area, where it is returned to local streams and rivers.

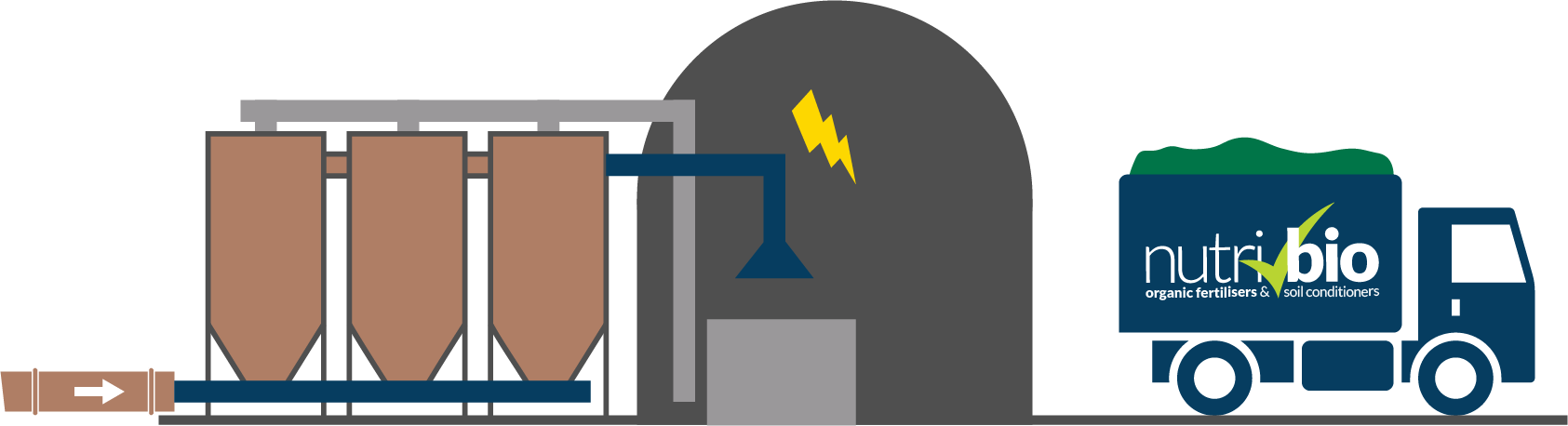

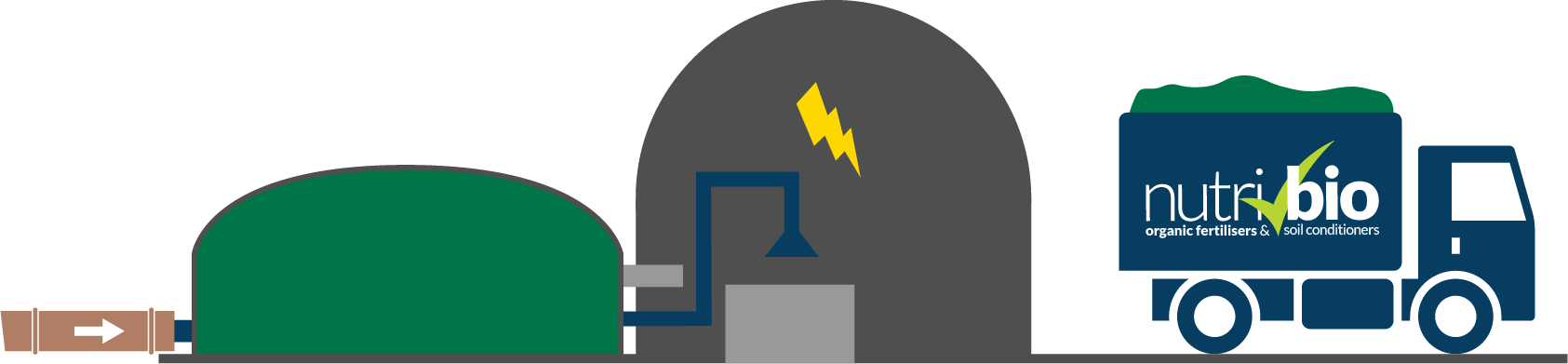

Cambi plants operate a thermal hydrolysis system, which treats the sludge through four biological processes. Before treatment the sludge is heated to 165 degrees centigrade. After a minimum of 13 days the biosolids, from the sludge, are ready for land.

Monsal plants use enzymic hydrolysis. The sludge goes through five digesters at a constant temperature of 40 degrees centigrade, which is then increased to kill any remaining pathogens. The biosolids are then ready for land.

The HPH plants treat the sludge with both thermophilic (heat-loving bacteria) and mesophilic (medium temperature loving bacteria), in a process called biological hydrolysis. The sludge is activated and pasteurised through three tanks at temperatures of up to 55 degrees centigrade. It then moves to more conventional anaerobic digestion for up to 13 days. This system leads to increased solids destruction and an enhanced standard of biosolid, with less odour!

There are 3 types of anaerobic digester used to make the biosolids 99% pathogen free (conventional standard). They can make the biosolids 99.9999% pathogen free (enhanced status). This is the equivalent to a surface wiped clean with bleach!